- City Fajr Shuruq Duhr Asr Magrib Isha

- Dubai 05:18 06:35 12:07 15:10 17:33 18:50

Fancy flying on a complete 3D printed plane with expandable seats, totally transparent walls built of bionic materials? The prototype still being worked on and according to Airbus, it might take well over two generations for the concept to become a reality.

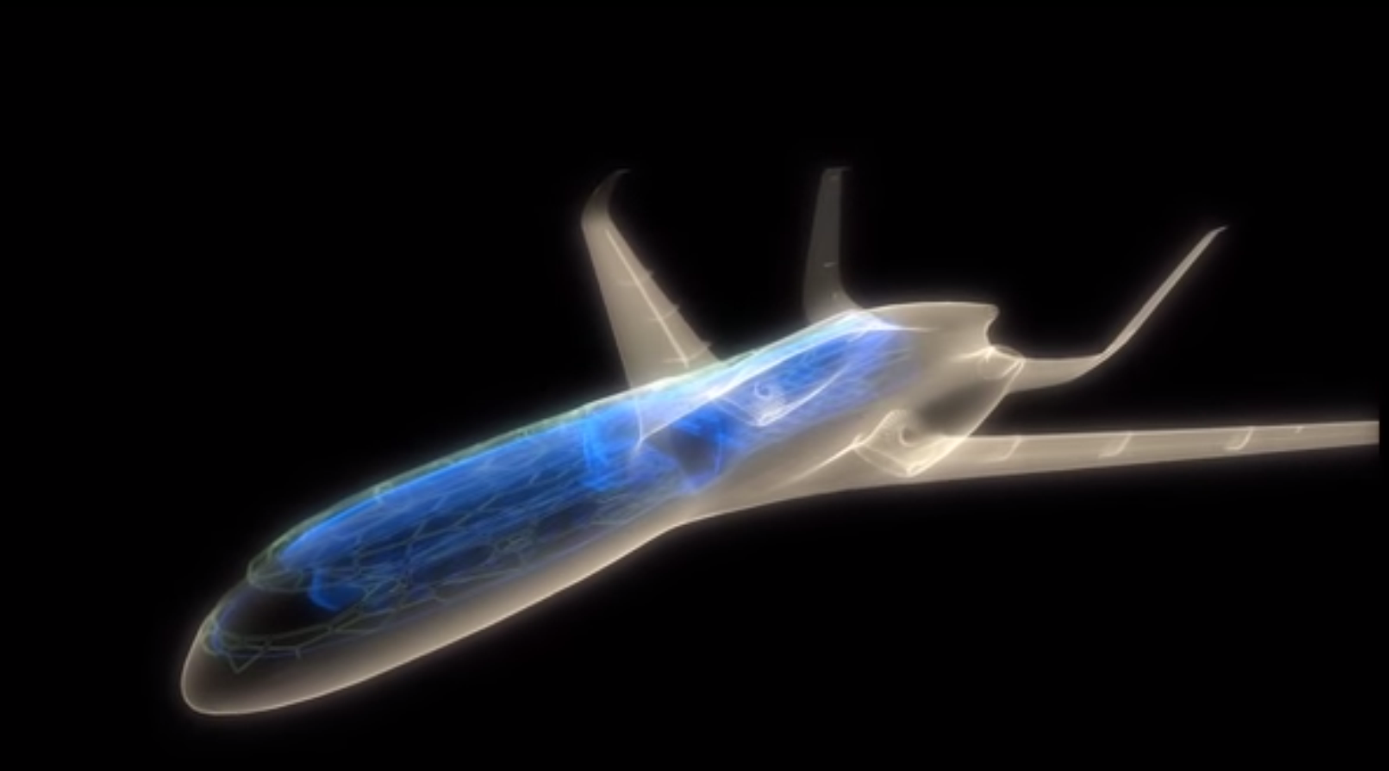

Airbus recently showcased the latest advancements to its concept cabin at the Autodesk Gallery in Paris and on display was its ultra-long and slim wings, semi-embedded engines, a 3D printed model of a U-shaped tail and as Airbus put it an lightweight intelligent body. According to Airbus its a whole new flying experience inspired by nature.

The idea was first unveiled in 2011 in what the company described as the Future of Airbus. The very next year the company put out another concept of its concept cabin and the interiors.

“We want to create a completely new experience to passengers who use a commercial airline. Our concept cabin showcases bionic structures. Last week we showcased a new material that can morph itself. We are working towards optimising it to use it in our cabins,” said Bastian Schaefer, Cabin and Cargo Innovation Manager at Airbus Operations.

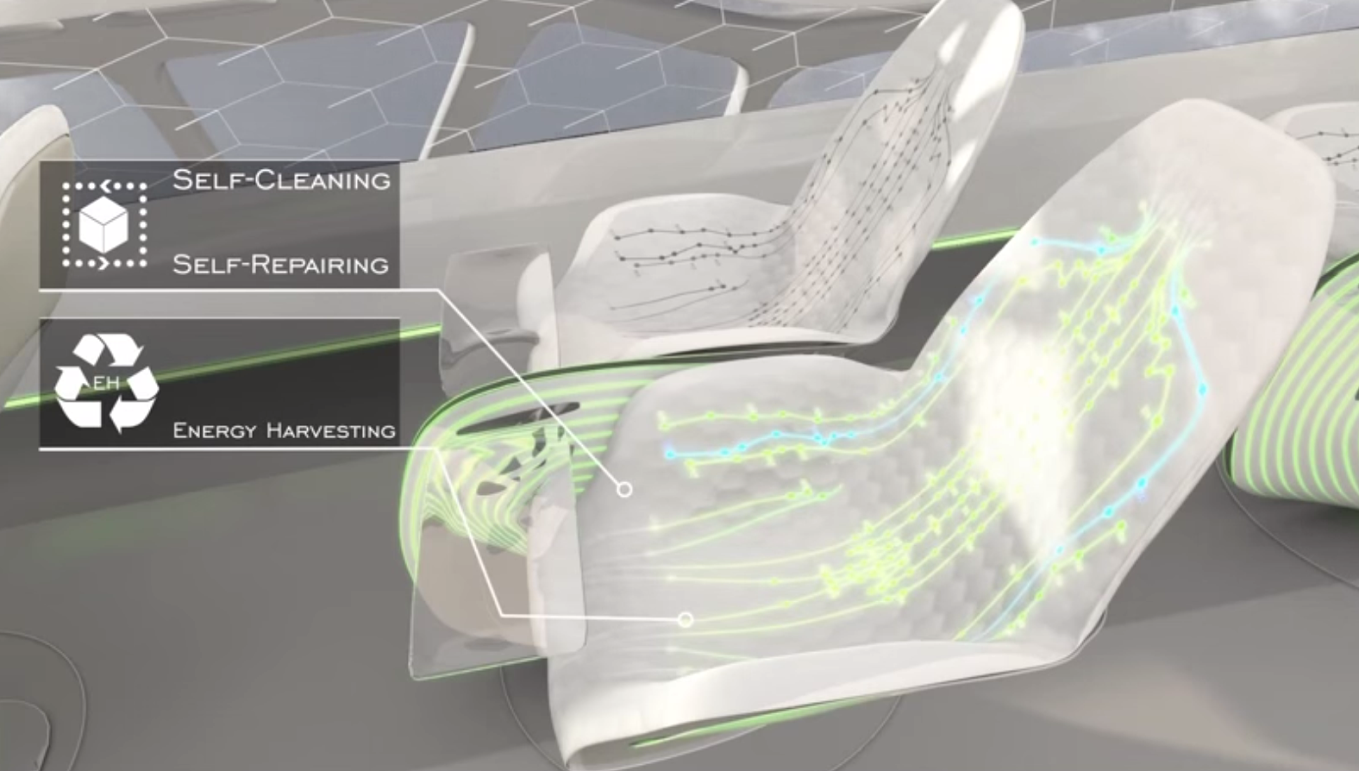

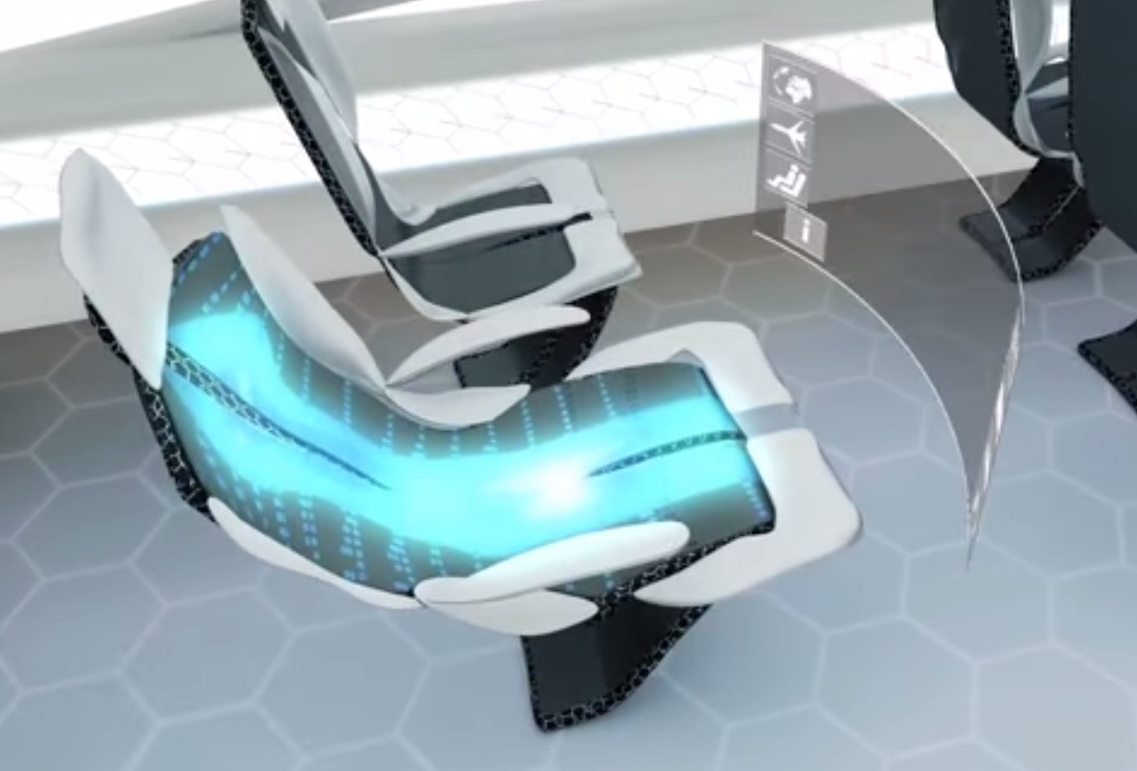

According to him one of the examples of the futuristic cabin would be seats that could adopt to the shape of the passengers.

The video below showcases the concept of future cabin by Airbus.

In some areas in western civilization, he says people are getting taller and at the same time more obese. “It is quite a growing number. Today we are dealing with a lot of standard parts and standard seats and the airliner would choose what kind of seats they prefer to buy and offer to their passengers.

We believe that if we could integrate certain type of morphing materials and new kind of seats, we could fulfill the needs of the passenger,” he said.

“The seats could be made of plastic or any new material that could emerge through new research. The technology is moving so fast and we are experimenting with new materials which could result in new solutions,” he said.

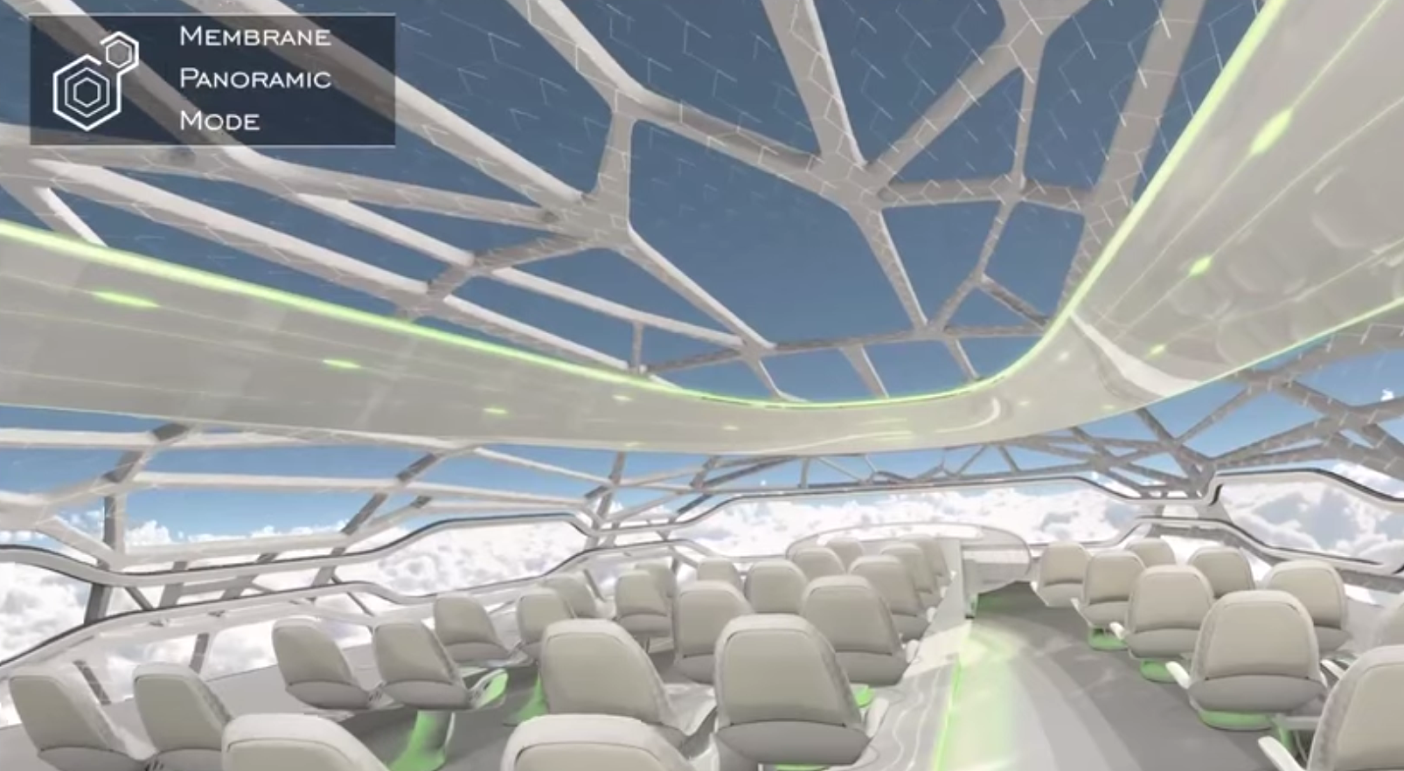

According to him another example is the combination of light and structural design.

“The bionic structure can fulfill perfectly the requirement. Our cabins will have a new kind of transparent material. You will not state of the art windows but very large transparent roof. We want to break the boundaries of our thinking. The idea is to make the airplane more efficient and at the same time very high passenger focused,” he said.

“We combine the new possibilities in optimization and in using algorithms that combine into design and into 3D printing these new style,” he ads.

Airbus has already introduced the first 3D printer built part when it fitted the A350 with a titanium bracket.

“We hope that we can start successfully with small parts and create bigger and bigger parts in the future. We are currently limited by the size of the printers. As soon as the size of the printers get larger we can come out with larger products,” says Schaefer.

The idea is to create large rivetless structures. “A complete solution for us currently is two generations away. Do not expect anything to be ready until 2050. But you never know what the future brings. It could be achieved much faster. the technology is evolving very fast,” he said.

Even the shape of the exterior could change. “What we currently see is that we are coming from a rectangular wall to a more bionic wall. We can create new structures and new shapes,” he added.

![]() Follow Emirates 24|7 on Google News.

Follow Emirates 24|7 on Google News.